Brief introduction and advantages of Intelligent Dock Leveler

Intelligent Dock LevelerIt can prevent dust and rain, isolate cold and heat, and provide reliable guarantee for rapid loading and unloading of goods. It is an indispensable and important equipment in industrial logistics.。The following is to introduce the Intelligent Dock Leveler:

1、Brief introduction of Intelligent Dock Leveler

Intelligent Dock LevelerAs the key facility of industrial logistics loading and unloading, it has the function of height adjustment, which can match the containers of transport vehicles with different heights.,The overall structural design is relatively simple and compact.,it is mainly composed of security apparatus/device/equipment, guide, elevating, control system and in public,it has the characteristics of Save space, Good durability, Comprehensive safety protection, Strong bearing capacity and Convenient maintenance,the advantage is Save space and rationally plan the layout of warehouse entrances and exits、Strong load-bearing performance, meet the requirements of all kinds of heavy cargo handling.、Various control modes are optional, and the operation is flexible and convenient.、Flexible and convenient operation, reducing labor intensity.、Strong load-bearing structure to ensure the safe loading and unloading of heavy-duty goods,can be customized according to user's needs.。

Intelligent Dock Leveler

2、Structural advantages of Intelligent Dock Leveler

The Intelligent Dock Leveler has the following structure

- structural support

- in public

- docking assembly

- control system

- structural support

The steel structure frame is welded with large section steel and connected with the reinforced concrete foundation through anchor bolts to ensure the stability of the platform.

Made of high-strength steel, the surface is treated with anti-slip, carrying forklifts and goods. At the bottom, steel beams such as channel steel and I-beam are welded as the skeleton to ensure the bearing performance.

The retractable strap extends out to connect with the truck compartment to form a loading and unloading channel; Some parts are equipped with automatic positioning system, which can quickly and accurately dock.

The operation button box is convenient for manual control; The remote controller realizes remote operation; The PLC controller intelligently manages the operation process and safety protection.

The steel structure frame is welded with large section steel and connected with the reinforced concrete foundation through anchor bolts to ensure the stability of the platform.

Intelligent Dock Leveler

3、Intelligent Dock Leveler performance advantage

Intelligent Dock Levelers have the following advantages.

- Adapt to a variety of scenarios

- Enhance security

- easy to operate

- Improve loading and unloading efficiency

- Strong and durable

It can be customized according to different use scenarios and needs. For example, in cold chain logistics, the unloading platform of cold storage has good thermal insulation performance and fast loading and unloading function; In the chemical industry, the unloading platform has special functions such as fire prevention, explosion prevention and corrosion prevention, which can meet the cargo loading and unloading needs of various industries.

Equipped with a variety of safety devices, such as limit switches, fences, truck stoppers, etc. The limit switch prevents the platform from lifting excessively, the guardrail protects the safety of personnel, and the truck stopper fixes the truck to avoid accidents such as slipping or rollover, which provides all-round safety guarantee for loading and unloading operations.

No matter the unloading platform controlled by hydraulic system or mechanical control, its operation is relatively simple. Generally, the lifting, expansion and contraction of the platform can be realized only by operating buttons or controllers, and some of them are equipped with remote control devices, which is convenient for operators to operate from a distance.

Through the height adjustment function, it can quickly dock with freight cars with different heights to form a horizontal passage. Forklift and other loading and unloading equipment can directly drive into the car for operation, and it is not necessary to manually carry goods up and down frequently, which greatly shortens the loading and unloading time. For example, in a logistics warehouse, it can significantly improve the speed of goods entering and leaving the warehouse.

Usually, high-strength steel is used to make countertops, which have strong structure, large bearing capacity and anti-slip patterns on the surface, and can be used stably for many years, reducing the later maintenance and replacement costs of enterprises.

Intelligent Dock Leveler

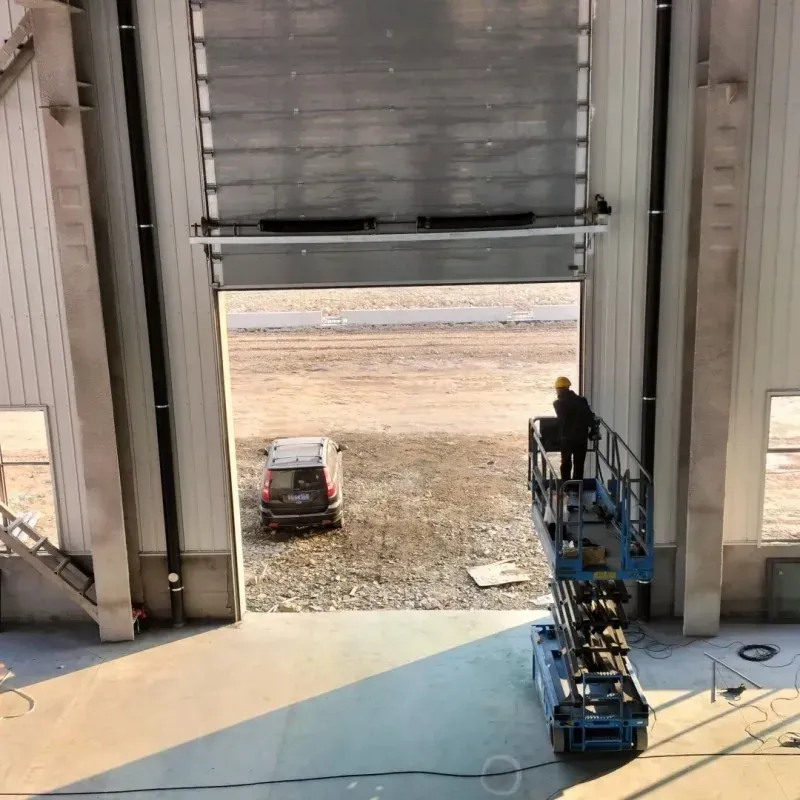

4、Physical picture of Intelligent Dock Leveler

The finished products of the Intelligent Dock Leveler factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Intelligent Dock Leveler

Note: All the pictures in this article were taken by Xuzhou speyer manufacturer.。

5、Intelligent Dock Leveler application

Intelligent Dock Levelers have the following purposes.

- Logistics center transshipment

- Warehouse cargo loading and unloading

- Loading and unloading of factory raw materials and finished products

- Warehouse cargo loading and unloading

- Logistics center transshipment

In the logistics center, realize the transit connection of goods with different modes of transportation and different routes, and improve the efficiency of logistics operation.

It is an important channel for goods to enter and leave the warehouse, which is convenient for goods to be quickly transferred from transport vehicles to warehouse storage or transported from warehouse to transport vehicles for distribution.

Such as shopping malls, supermarkets and other commercial places, are used to receive the goods sent by suppliers and ensure that the goods are sold on shelves in time.

It is an important channel for goods to enter and leave the warehouse, which is convenient for goods to be quickly transferred from transport vehicles to warehouse storage or transported from warehouse to transport vehicles for distribution.

The factory is used for loading and unloading raw materials, ensuring production and supply, and loading finished products for delivery to meet the market demand.

Intelligent Dock Leveler

6、Real-time shooting in Speyer's production workshop

The finished products of the Intelligent Dock Leveler factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Xuzhou speyer

The finished products of the Intelligent Dock Leveler factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Intelligent Dock LevelerSturdy and durable, suitable for high-intensity and high-frequency usage scenarios.、Seamless connection with warehouse management system to realize intelligent management.、Can quickly dock the truck with the warehouse, reducing the cargo handling distance.、Reduce the loss of goods during loading and unloading, and reduce the operating cost of enterprises.、Equipped with safety protection device to provide reliable guarantee for loading and unloading operations.,in the course of work,Using hydraulic system or mechanical device, the platform can be lifted and lowered to match the freight cars with different heights, so as to ensure that the goods can be loaded and unloaded on the same horizontal plane and reduce the drop and manpower consumption in the handling process.。

Related Recommendations

-

Introduction to Unmanned Forklift and Spiral Door and High speed Spiral Door working principle

2025-6-16 -

Introduction to Dust-Free Workshop Spiral Door, how much is the price of the High speed Spiral Door?

2025-6-16 -

Introduction to Vertical folding Garage Door, Garage Door advantages, characteristics and principles

2025-6-16 -

Introduction to Aluminum alloy Garage Door and Garage Door advantages and features

2025-6-16 -

Introduction to Parking Spiral Door, introduction to High speed Spiral Door advantages and characteristics

2025-6-16 -

What is a Automated Equipment High-Speed Door ? High-Speed Door specifications, models, and parameters

2025-6-16 -

What is a Large-Scale Industrial Spiral Door? Introduction to the advantages and characteristics of the High speed Spiral Door

2025-6-16 -

Introduction to Dust-Free Workshop Roller Shutter Spiral Door and High speed Spiral Door advantages and features

2025-6-16 -

What is a Underground Parking High-Speed Door ? Introduction to the advantages and characteristics of High-Speed Door functions

2025-6-16 -

Introduction to Industrial Workshop Use Spiral Door, advantages, characteristics and principles of High speed Spiral Door

2025-6-16