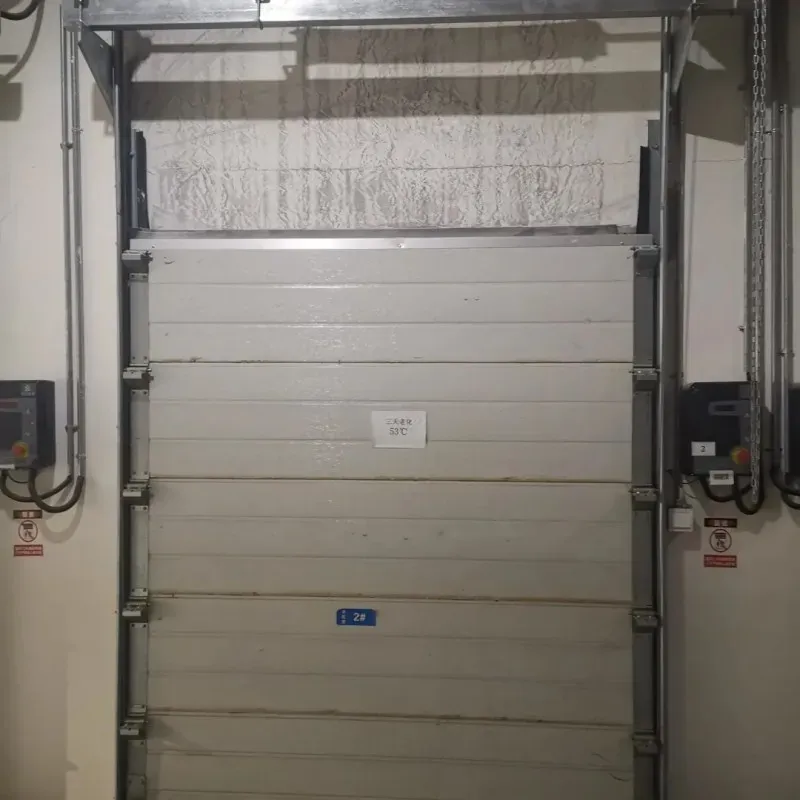

Brief introduction and advantages of Logistics Loading and Dock Leveler

Logistics Loading and Dock LevelerIt can prevent dust and rain, isolate cold and heat, and provide reliable guarantee for rapid loading and unloading of goods. It is an indispensable and important equipment in industrial logistics.,it has been widely used in medicine, airport, automobile, new energy, cold store and other industries,be of high quality,The price is relatively low.。

1、Brief introduction of Logistics Loading and Dock Leveler

Logistics Loading and Dock LevelerIt is an efficient and practical industrial loading and unloading equipment, which is widely used in the entrances and exits of various industrial plants, e-commerce warehouses, cold chain logistics and other places, and can quickly build a safe and stable loading and unloading channel.,It can be used for Loading and unloading of factory raw materials and finished products, Distribution of goods in commercial places, Logistics center transshipment, Distribution of goods in commercial places, Warehouse cargo loading and unloading, Loading and unloading of factory raw materials and finished products and so on。

Logistics Loading and Dock Leveler

2、Structural advantages of Logistics Loading and Dock Leveler

The Logistics Loading and Dock Leveler has the following structure

- control system

- docking assembly

- security apparatus/device/equipment

- structural support

- guide

The operation button box is convenient for manual control; The remote controller realizes remote operation; The PLC controller intelligently manages the operation process and safety protection.

The retractable strap extends out to connect with the truck compartment to form a loading and unloading channel; Some parts are equipped with automatic positioning system, which can quickly and accurately dock.

The limit switch controls the lifting height; The overload protection device monitors the weight; Fence to prevent people and goods from falling; The truck stopper fixes the vehicle.

The steel structure frame is welded with large section steel and connected with the reinforced concrete foundation through anchor bolts to ensure the stability of the platform.

Guide rails are installed on both sides to cooperate with the guide wheels on the platform, so as to ensure that the platform does not shake or deviate when lifting and running smoothly.

Logistics Loading and Dock Leveler

3、Logistics Loading and Dock Leveler application

Logistics Loading and Dock Levelers have the following purposes.

- Logistics center transshipment

- Loading and unloading of factory raw materials and finished products

- Logistics center transshipment

- Loading and unloading of factory raw materials and finished products

- Logistics center transshipment

The factory is used for loading and unloading raw materials, ensuring production and supply, and loading finished products for delivery to meet the market demand.

Such as shopping malls, supermarkets and other commercial places, are used to receive the goods sent by suppliers and ensure that the goods are sold on shelves in time.

In the logistics center, realize the transit connection of goods with different modes of transportation and different routes, and improve the efficiency of logistics operation.

Such as shopping malls, supermarkets and other commercial places, are used to receive the goods sent by suppliers and ensure that the goods are sold on shelves in time.

The factory is used for loading and unloading raw materials, ensuring production and supply, and loading finished products for delivery to meet the market demand.

Logistics Loading and Dock Leveler

4、Structural characteristics of Logistics Loading and Dock Leveler

The Logistics Loading and Dock Leveler has the following structure

- control system

- docking assembly

- elevating

- in public

- security apparatus/device/equipment

The operation button box is convenient for manual control; The remote controller realizes remote operation; The PLC controller intelligently manages the operation process and safety protection.

The retractable strap extends out to connect with the truck compartment to form a loading and unloading channel; Some parts are equipped with automatic positioning system, which can quickly and accurately dock.

Common hydraulic type, which consists of hydraulic pump station, hydraulic cylinder and hydraulic pipeline, has sufficient power and stable lifting; There are also mechanical types, which are driven by lead screws, nuts, chains, etc., with simple structure.

Made of high-strength steel, the surface is treated with anti-slip, carrying forklifts and goods. At the bottom, steel beams such as channel steel and I-beam are welded as the skeleton to ensure the bearing performance.

The limit switch controls the lifting height; The overload protection device monitors the weight; Fence to prevent people and goods from falling; The truck stopper fixes the vehicle.

Logistics Loading and Dock Leveler

5、Logistics Loading and Dock Leveler characteristics

The Logistics Loading and Dock Leveler features are as follows:

- durability

- Convenient maintenance

- Wide application range

- Save space

- Comprehensive safety protection

Made of high-quality materials, the surface is rustproof and wear-resistant, which can adapt to the complex and harsh working environment such as warehouses and docks and prolong the service life of the equipment.

The structure design is reasonable, the key components are easy to check and replace, and the equipment can be maintained in good running condition only by simple maintenance work such as lubrication and cleaning.

Whether it is a logistics warehouse, a factory workshop, a port, or a place with special requirements for the environment such as cold chain logistics, it can play an important role.

Some unloading platforms are designed to be foldable or telescopic, which can be stored when not in use, thus reducing the occupation of the site space and improving the space utilization rate.

There are fences to stop people from falling accidentally, limiters to prevent the platform from lifting excessively, warning lights to indicate the working status, and some trucks are also equipped with stoppers to fix vehicles.

Logistics Loading and Dock Leveler

Logistics Loading and Dock Levelerthe product looks atmospheric.,it is widely used in new energy, airport, cold store, medicine, automobile and other industries,Mainly used forLogistics center transshipment,Distribution of goods in commercial places,Loading and unloading of factory raw materials and finished products,Logistics center transshipment andWarehouse cargo loading and unloading。

Related Recommendations

-

Introduction to Workshop flip plate Garage Door, Garage Door specifications, model parameters

2025-6-16 -

What is a Heavy-duty track Sectional Door? How much is the price of the Sectional Door?

2025-6-16 -

What is a Large Automatic Fast Door ? Introduction to the advantages and characteristics of the PVC FAST Door

2025-6-16 -

Introduction to Workshop Fast Door for Cold Storage and PVC FAST Door structure principle

2025-6-16 -

Introduction to Air Shower Soft High-Speed Door , introduction to High-Speed Door advantages and characteristics

2025-6-16 -

Introduction to Horizontal fast stacking door, advantages, characteristics and principles of Stacking Rapid Door

2025-6-16 -

Introduction to Garbage Treatment Plant High-Speed Door , introduction to High-Speed Door advantages and characteristics

2025-6-16 -

Introduction to Large Folding High-Speed Door , introduction to High-Speed Door function advantages and characteristics

2025-6-16 -

Introduction to Industrial flip panel Garage Door, introduction to Garage Door advantages and characteristics

2025-6-16 -

What is a Fire Brigade Electric High-Speed Door ? Introduction to the Working Principle of High-Speed Door

2025-6-16